Newton Total Concrete - Frequently Asked Questions

If Your Question Is Not Answered Here Drop Us A Line

Can concrete surfaces be economically installed as overlays on existing degraded concrete bases in Newton?

Overlay installations function effectively over existing concrete foundations provided base surfaces demonstrate structural soundness, thorough cleanliness, and absence of major structural compromise. You can’t build a new concrete patio in Newton if there is an old concrete slab sitting on the site that must be destroyed and removed properly. Thin overlay applications deliver attractive cosmetic revitalization, though substantial structural repairs demand complete removal and new installation.

What expenditure range should homeowners anticipate for concrete driveway installations in Newton?

As of 2025, the average costs that homeowners paid for driveway installation in Middlesex County are between $1,391 and $6,582. When taking into account all the factors that affect cost, on the low end of the scale, a job could cost under $2,000, while more complex work on larger areas could reach several thousand dollars. These estimates provide a foundation for budgeting, though site-specific factors and contractor selection influence final project costs.

What premium do decorative or stamped concrete finishes command compared to standard installations?

Average costs to stamp concrete are $16-$20 per square foot for typical Massachusetts projects. Adding decorative elements substantially increases base concrete expenses. High-end artistic applications combining multiple techniques like stamping, staining, and hand-detailed finishes can reach $25 or more per square foot. Weigh aesthetic enhancements carefully against your overall project budget.

What cost differential exists between complete driveway replacement and resurfacing solutions?

Full replacement typically costs two to three times more than resurfacing. Resurfacing addresses cosmetic issues like minor cracks, surface wear, and discoloration without requiring complete removal and reconstruction. Full replacement becomes necessary when the driveway exhibits significant structural damage, deep cracks, major settling, or extensive deterioration. Newton’s freeze-thaw environment often necessitates replacement more frequently than drier regions.

Are building permits required for concrete driveway and patio installations in Newton?

The Inspectional Services Department (ISD) is responsible for ensuring that buildings are constructed safely and used properly. ISD enforces the provisions of the state building code, city zoning ordinance, and other applicable ordinances. ISD issues permits to allow the construction, reconstruction, alteration, repair, and demolition of buildings and structures. Most concrete work in Newton requires a building permit.

What specifications does the Massachusetts Building Code establish for concrete installations?

Nonstructural concrete must have a minimum specified compressive strength of 2,500 psi for Class F0; 3,000 psi for Class F1; and 3,500 psi for Classes F2 and F3. Massachusetts regulations align with national standards for concrete specifications, strength ratings, and reinforcement protocols. Consult with licensed contractors familiar with the Massachusetts Building Code for compliance guidance specific to your project scope.

What inquiries should homeowners direct toward concrete contractors before finalizing hiring agreements?

Ask about the current state of contractor licensing, proof of adequate insurance protection, references from recent Newton-area projects, comprehensive project timeline estimates, post-installation cleanup plans, warranty specifics and coverage limitations, joint placement and slope management strategies, and demonstrated understanding of Massachusetts climate demands, including freeze-thaw protection. Transparent contractor communication prevents misunderstandings and facilitates superior outcomes.

Must building permits be secured before concrete work commences in Newton?

Yes, the building permit must be obtained before the start of any work and prominently displayed at the job site. Commencing work without obtaining required permits can result in significant fines, forced project halts, and mandatory remediation. Always verify permit requirements with municipal authorities and secure authorization before breaking ground on any concrete project.

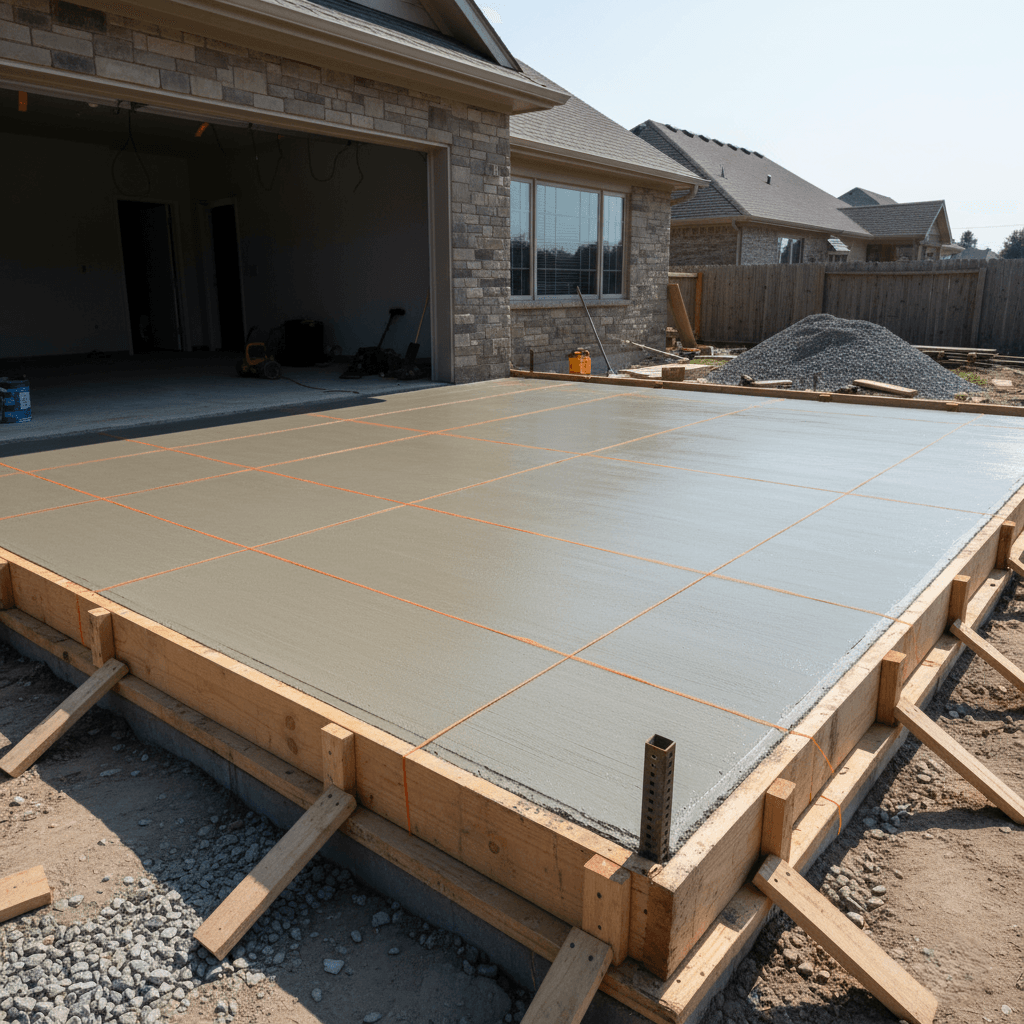

What slope gradient should Newton driveways and patios incorporate for effective water management?

A slope gradient of 1/8 inch to 1/4 inch per foot facilitates water drainage away from structures. Proper grading proves critical in Newton to prevent standing water accumulation, which accelerates surface deterioration, encourages algae colonization, and creates safety hazards. Inadequate drainage substantially reduces surface lifespan through repeated water infiltration and destructive freeze-thaw cycles.

Are small hairline cracks normal in concrete installations, or do they indicate structural concerns?

Hairline cracks resulting from natural concrete shrinkage are generally acceptable and do not indicate structural defects. While it is true that Newton driveway concrete pavers can crack over time, it usually takes a while before you start to notice this problem. Wide cracks that expand progressively may signal settlement, foundation stress, or freeze-thaw damage requiring professional evaluation.

Will winter de-icing chemicals harm concrete in Newton, and which ice melt alternatives are recommended?

Chloride-based de-icing salts cause surface scaling, spalling, and structural deterioration when applied repeatedly. When Newton experiences winter conditions, calcium chloride or salt-free ice melt products offer safer alternatives. Pre-season protective sealing provides insurance against road salt and repeated freeze-thaw damage. Professional snow removal services reduce reliance on chemical treatments that compromise concrete durability.

What weather conditions prove optimal for scheduling concrete installation activities in Newton?

Spring through early autumn generally presents favorable conditions for pouring concrete in Newton. Temperatures between 50-85 degrees Fahrenheit provide ideal conditions. Avoid scheduling pours when nighttime temperatures approach freezing, as concrete requires warmth to cure properly. Newton’s unpredictable weather patterns may necessitate flexibility and contingency planning. Professional contractors monitor forecasts and schedule work strategically.

What distinguishes sealed concrete from unsealed concrete, and does protective sealing truly prevent environmental damage in Newton?

Sealed concrete resists staining, moisture infiltration, and freeze-thaw damage. Unsealed installations demonstrate vulnerability to cracking, deterioration, surface discoloration, and efflorescence development. In Newton’s challenging climate with repeated freeze-thaw cycles and road salt applications, sealing represents an essential investment in surface longevity. Regular resealing every two to three years maintains protection effectiveness.

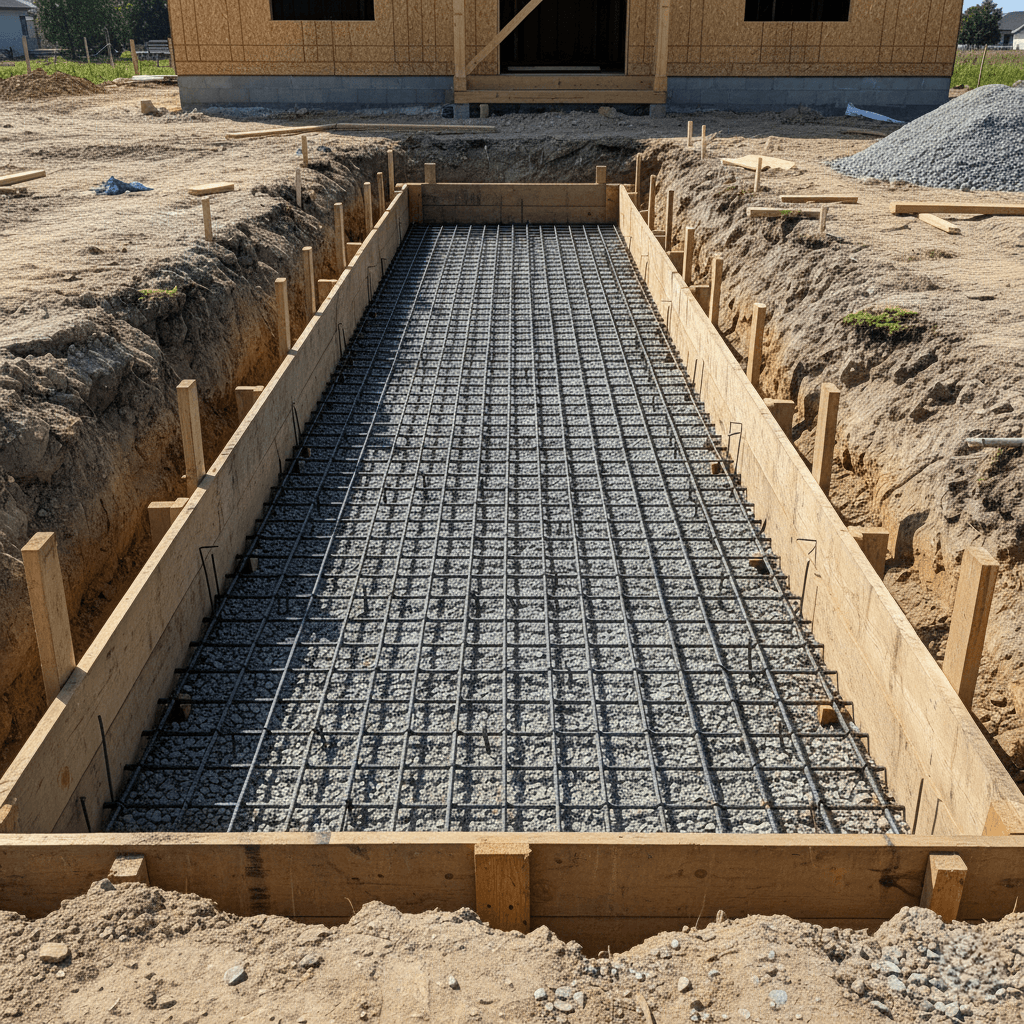

Does heavy vehicle traffic influence driveway design specifications and reinforcement requirements in Newton?

Heavy vehicles, including recreational vehicles, commercial trucks, and specialty equipment demand thicker slab installations (5-6 inches), enhanced reinforcement utilizing rebar components, and thoroughly compacted base materials. Standard residential specifications may demonstrate cracking vulnerability under frequent heavy-load conditions. Communicate anticipated traffic patterns and load expectations to contractors during design consultations.

What factors influence the total cost per cubic yard when ordering ready-mix concrete for Newton projects?

Several factors impact concrete pricing. Short-load premiums apply to orders under minimum quantities. Equipment rental for pump truck access occurs when site conditions are constrained. Transportation costs vary based on distance from supplier facilities. Specialty chemical additives for freeze-thaw protection increase material costs. Winter weather conditions may also affect pricing and availability.

What price range should be expected for stamped concrete alternatives compared to standard broom-finished installations?

Stamped concrete typically adds $3-$8 per square foot over plain broom-finished surfaces. Simple decorative enhancements, such as color accents or borders, add $2-$5 per square foot. Premium decorative finishes combining multiple techniques and artistic elements can exceed standard pricing considerably. Weigh aesthetic improvements against budget constraints.

What thickness should residential driveway concrete slabs be in Newton?

Standard residential driveways in Newton typically utilize a 4-inch thickness as a baseline specification. For properties anticipating heavier vehicle usage, recreational vehicle storage, or commercial vehicle traffic, a 5-6 inch thickness provides enhanced durability. Thicker sections reduce cracking probability and extend service intervals, proving especially valuable in Newton’s freeze-thaw environment.