Designing Slabs That Resist Frost Movement in Newton Winters

Concrete Slab Newton

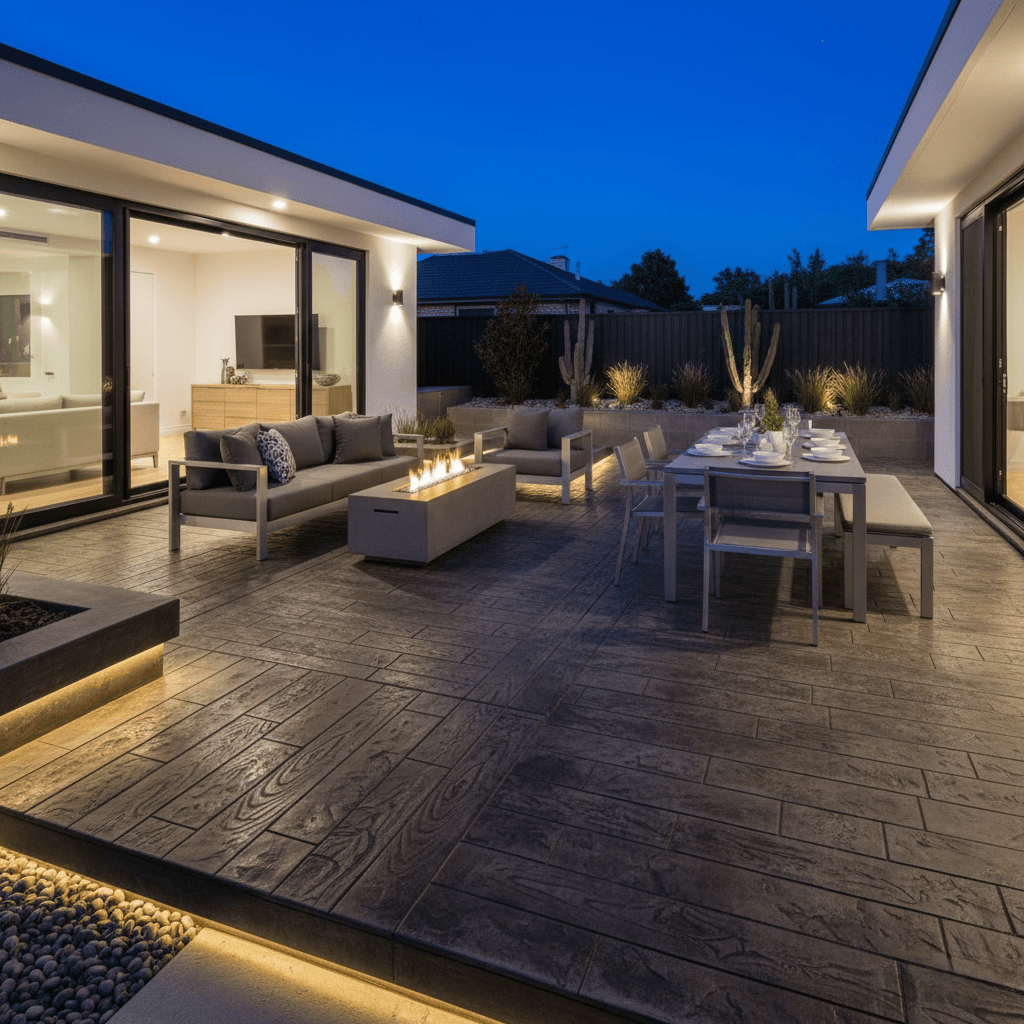

The freeze-thaw cycle is the most damaging weather condition to the durability and structural integrity of concrete flat work (patios, shed bases, etc.), as well as concrete garage floors in New England. A “freeze-thaw” cycle will cause frost heaving or the upward expansion of a concrete slab due to the water turning into ice. If a slab does not have sufficient design and/or installation to prevent this type of heaving, it will be subject to cracking and lifting. Therefore, the installer of a concrete slab in Newton must have some basic understanding of the environmental conditions of New England and how to apply engineering techniques to minimize the damage from the freeze-thaw cycle. In addition to having a basic understanding of the regional climate conditions, a successful installer must also be aware of site preparation, drainage, insulation, and the selection of the concrete mix design.

Identify and Mitigate the Source of Frost Heaving: Frost-Sensitive Soil

Frost heave occurs due to expansion resulting from water within the soil freezing; therefore, there are three basic conditions required for frost heaving to occur. Those conditions include frost-sensitive soil, water availability, and cold temperatures. We will first examine the frost-sensitive condition in the soil.

Replace Native Fill Material with Non-Frost Sensitive Granular Material

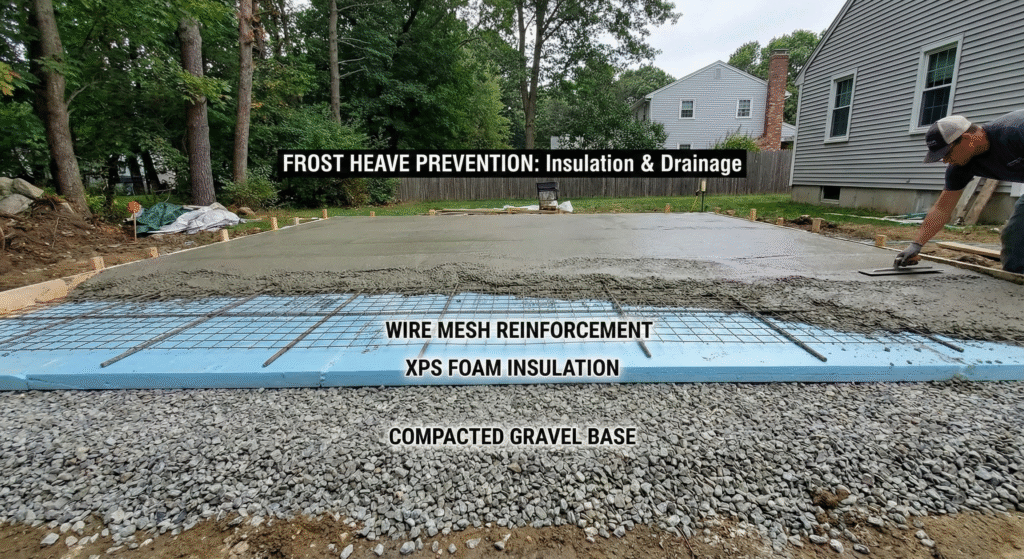

Native soils located in many areas of Newton contain large quantities of silt and clay, making these soils extremely sensitive to frost heave. In order to minimize the potential for frost heave to occur, professionals involved in constructing a concrete slab must dig out the area and replace the native soil under the concrete slab with a thick layer of non-frost-sensitive, free-draining granular fill material. The most common type of material used is crushed aggregate, or well-graded aggregate, that does not retain water, thereby minimizing the likelihood of ice formation beneath the slab.

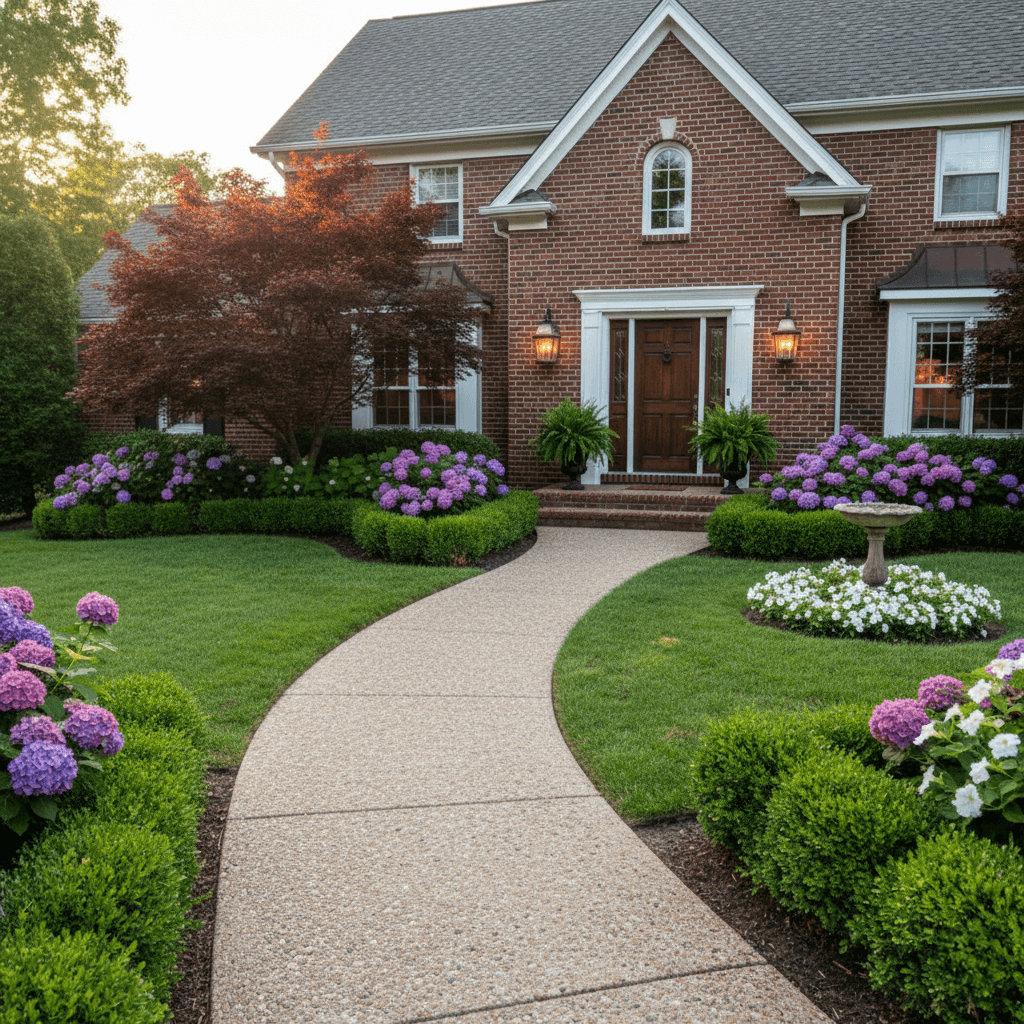

Properly Directing Moisture Away From the Slab

Just as important as ensuring the soil is prepared properly is ensuring that no water exists to create ice in the soil. It is imperative that the surrounding area of the slab be properly graded so that surface water does not collect near the foundation. Proper grading will allow us to install perimeter drains, or French drains, to capture all subsurface moisture and keep the area beneath the slab as dry as possible. By implementing a comprehensive drainage system around the slab, we can ensure that even extreme temperatures have little to no impact on the soil beneath the slab.

Enhanced Slab Design and Rebar Installation

After addressing the soil preparation, the next consideration must be the design of the slab itself. Specifically, we need to design the slab to effectively resist both horizontal and vertical loads.

Additional Edge Thickness and Reinforcement

While a 4″ thick slab may be sufficient for a lightly used application, in colder climates like Newton, it is beneficial to increase the thickness of the perimeter edge of the slab, typically known as a thickened edge slab or grade beam. This added thickness provides increased structural support to the slab at the point where the slab meets the earth. Within the slab, steel reinforcement (rebar) is installed inside the slab to maintain the integrity of the slab if it develops cracks. As previously stated, the purpose of the steel is to prevent excessive movement of the slab, thereby protecting against the harsh effects of frost heave.

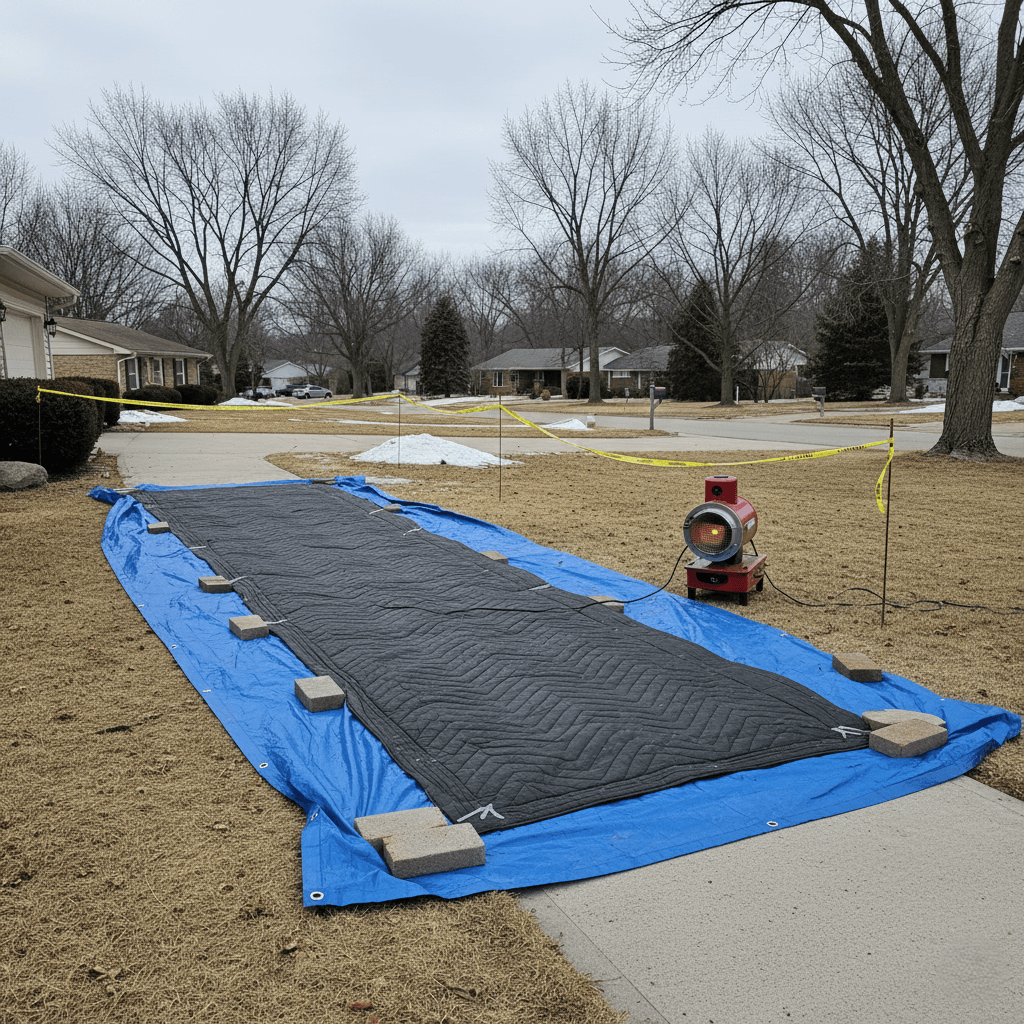

Concrete Insulation

For residential applications, such as those for heated structures (residential dwellings, attached garages, etc.), we install rigid foam insulation, usually in the form of extruded polystyrene (XPS), directly beneath the slab. This insulation serves as a thermal break between the heated structure and the earth, preventing heat loss into the earth. Furthermore, this insulation keeps the earth beneath the slab warmer than the earth would otherwise be, which has the effect of extending the length of time the water beneath the slab remains unfrozen. In essence, this insulation is an excellent method to combat the penetration of cold through the slab and mitigate the occurrence of frost heave.

Using High-Performance Concrete Mix Designs

Air-Entrained Concrete to Reduce Damage to the Slab’s Surface

When water freezes, it expands and creates internal pressure, which can lead to the spalling of the slab’s surface. Air-entrained concrete includes small air pockets that act as pressure relief valves to help alleviate the internal pressure caused by the expanding water. When using air-entrained concrete, the risk of damage to the surface of the slab due to moisture and de-icing salt used on adjacent roadways and walkways (such as those around the Chestnut Hill Reservoir) is significantly reduced.

Lower Water-to-Cement Ratios to Minimize Permeability

The water-to-cement ratio of a concrete mix has a significant influence on the overall porosity of the hardened concrete. Therefore, when the water-to-cement ratio is minimized, the concrete becomes less porous and, subsequently, less permeable to water. With less water available to enter the slab, there is less opportunity for the water to freeze and create damage. By careful control of the water-to-cement ratio during the mixing process, we are able to manufacture slabs that are more resistant to environmental degradation over time.

Installation and Post-Pour Protection

Installation of Vapor Barriers

Prior to pouring the concrete, a polyethylene vapor barrier must be placed directly beneath the slab. The vapor barrier minimizes the amount of moisture that enters the concrete from the subgrade. For interior slabs, this barrier is critical to maintaining consistent moisture levels throughout the slab. However, the vapor barrier also aids in regulating moisture in exterior applications. Additionally, a continuous vapor barrier maintains consistent moisture levels throughout the slab’s service life.

Newton Specifics

We have extensive knowledge of Newton’s local microclimates and all specific permitting requirements for engineered slabs. Our experience allows us to tailor each element of the slab’s construction (from the subgrade to reinforcement placement) to meet or exceed the strictest guidelines for cold-climate construction in Newton.

Constructing a concrete slab capable of enduring the extreme freeze-thaw cycles present in Newton’s winters is dependent upon the precise engineering of the slab and the utilization of superior, high-quality materials. Ensuring the slab performs as desired is dependent upon the sub-grade preparation, insulating the pour, and selecting high-performance concrete mixes to protect the slab from the detrimental effects of frost heave. To discuss your slab project, please contact Newton Total Concrete.