Best Practices for Pouring Concrete in Newton Cold Snaps

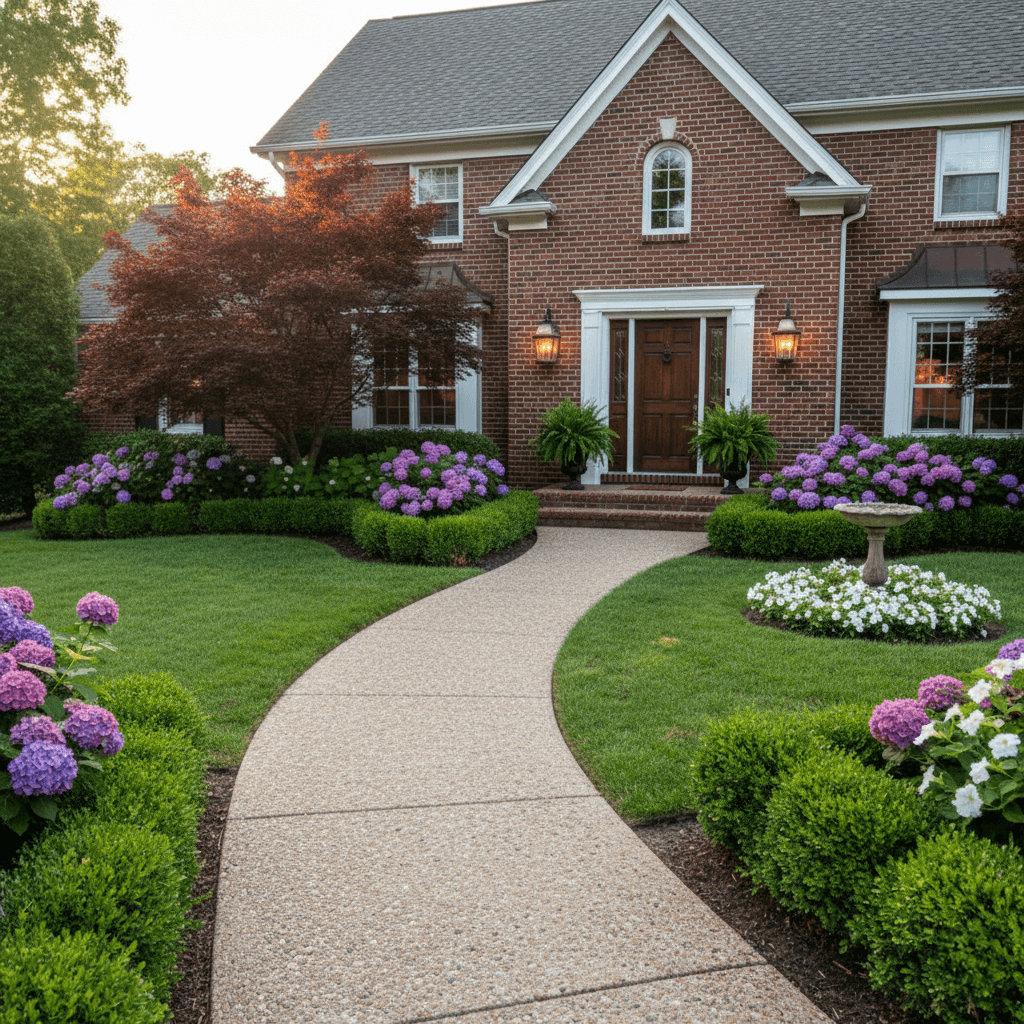

Pouring Concrete Newton

Construction time frames for many projects in Newton are very long; so many jobs have to be poured with the cold weather of late Fall and Early Winter. Concrete is a critical part of this process, as the hydration (curing) process is greatly slowed or stopped at 40 degrees F or lower. If you do not take proper measures to keep the concrete from freezing prior to achieving the required strength, the structure will be weakened, scale off, and fail, resulting in expensive loss to the contractor. Contractors must follow strict cold weather practices, maintaining the material at appropriate temperatures and moisture to allow for the curing to occur properly and allow for the desired durability.

Preparation: Before the Mix Arrives

Preparation of the site and its surroundings before the concrete truck arrives at the site is an integral part of the cold-weather process for successful, quality-poured concrete. The pre-pour preparation is vital to achieving and maintaining thermal stability.

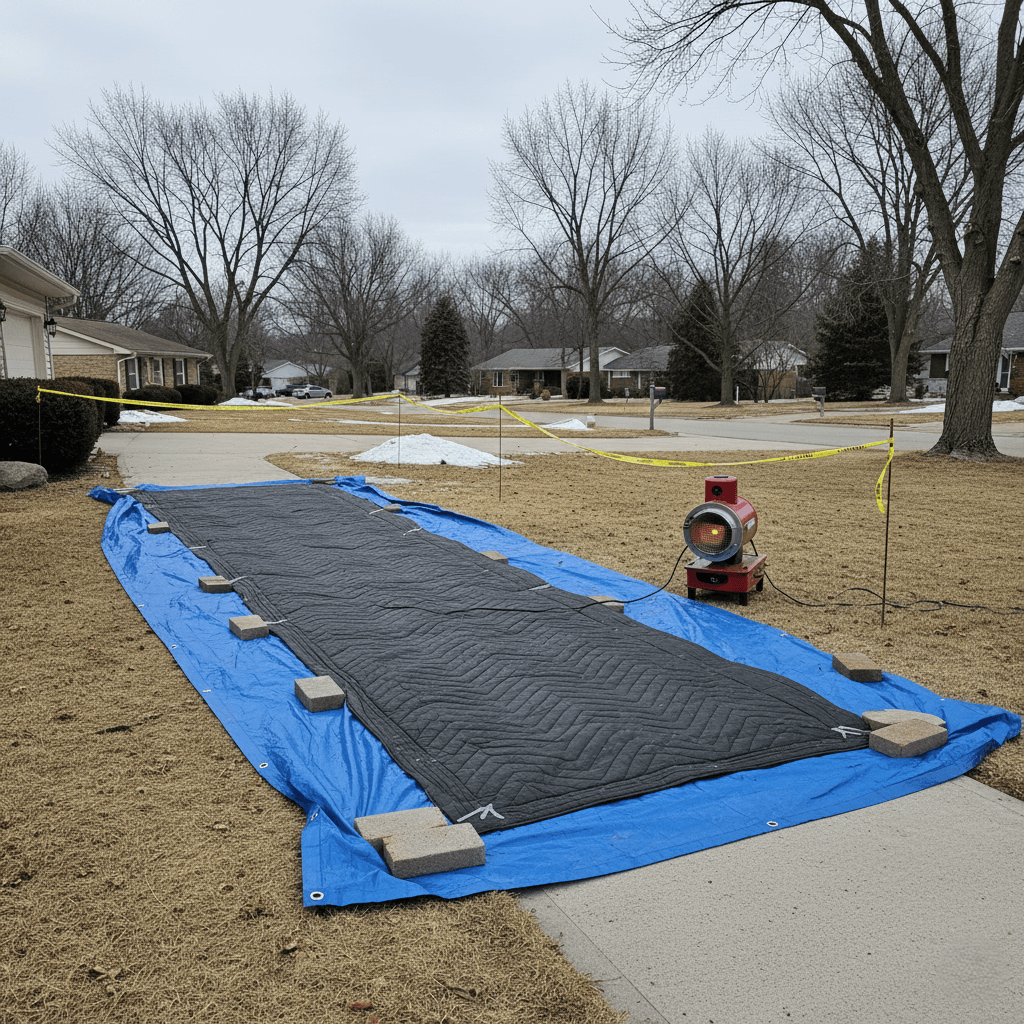

Heating the Subgrade & Forms

Pouring freshly mixed concrete onto a frozen subgrade will result in rapid heat loss to the subgrade. Therefore, we use ground heaters or thermal blankets to raise the temperature of the subgrade and forms at least 24 hours before the pour. This ensures that the temperature of all contact surfaces will be above freezing to provide the best possible initial curing conditions and prevent flash freezing of the newly placed concrete.

Protection from Wind & Rain/Snow

Wind chill, along with direct snow or rain exposure, greatly reduces the surface temperature of the concrete. We install temporary wind breaks or full heated enclosures around the pour area to protect the curing concrete from losing additional heat to the environment, as well as from moisture contamination. This is especially important around open, windy areas such as large commercial slabs or driveways.

Adjusting the Standard Concrete Mix Design for Cold Weather

Specialized additives must be added to the standard concrete mix design to accelerate the curing process at low ambient temperatures.

Use of Chemical Accelerators

Non-chloride calcium chloride or non-chloride accelerating admixtures are added to the mix to accelerate the hydration reaction and shorten the time required for the concrete to reach its critical set strength, reducing susceptibility to freezing. Although they accelerate the curing process, the chemicals used as accelerators will not prevent the concrete from freezing, so external heat protection is always necessary.

Control of Fresh Concrete Temperature

The temperature of the fresh concrete when delivered to the job site should be controlled between 50 and 70 degrees F, depending on the ambient temperature. This is accomplished by heating the mixing water and aggregate material before batching. Contractors constantly check the temperature of the concrete as it leaves the plant to ensure it meets the temperature requirements for the ambient conditions in the Newton area.

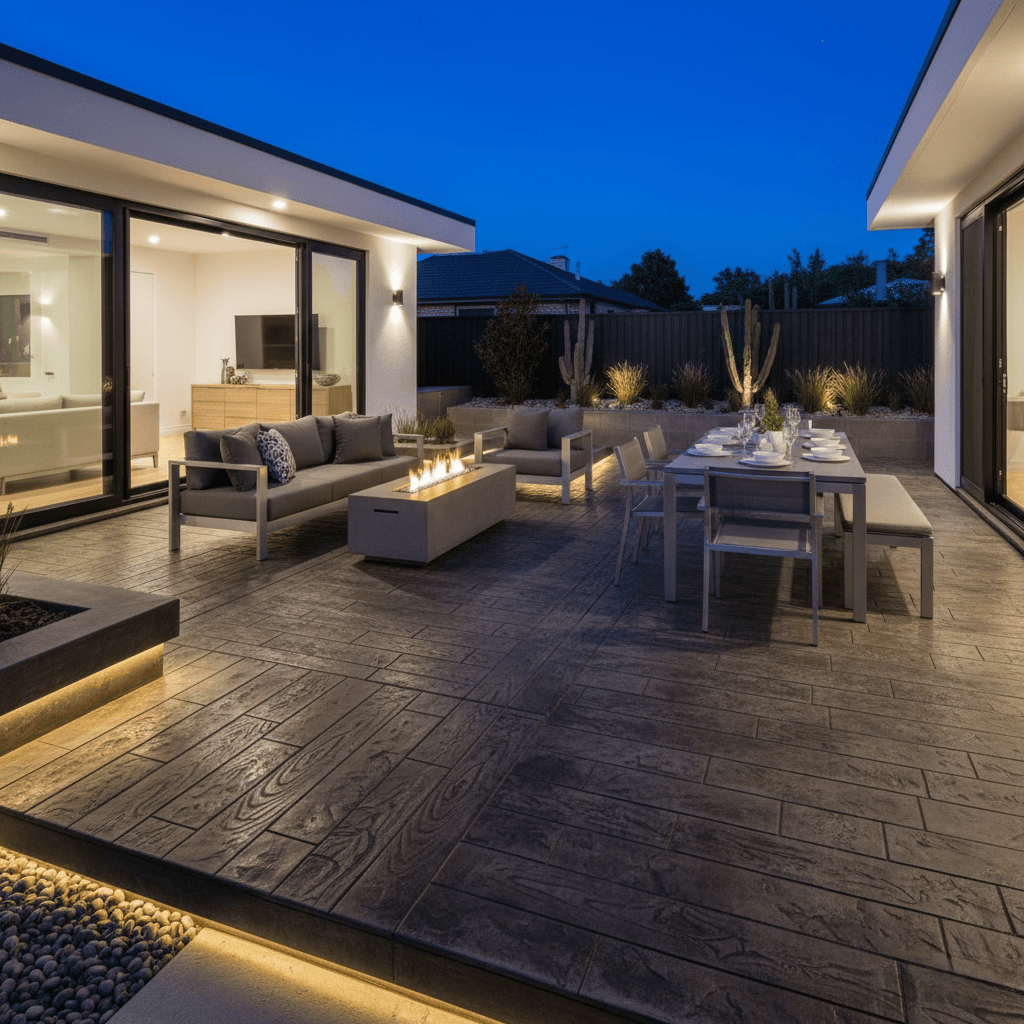

Curing: The Critical Period After Pouring

The most critical period for cold-weather concrete is the first 72 hours. During this time, the mix must be protected to prevent freezing.

Insulated Curing Blankets

Once the finishing operations are complete, the concrete must be covered with heavy-duty insulated curing blankets. The purpose of the curing blankets is to contain the heat produced by the hydration reaction, enabling the concrete to continue curing without heat loss. In extreme cold temperatures, or for very thin sections, a second layer of blankets or a heated enclosure may be needed to maintain the concrete temperature above 50 degrees F.

Adequate Moisture Levels

Moisture is required for hydration. If the air within the enclosure becomes too dry, the concrete can dehydrate prematurely. We add water or curing compound to the surface of the concrete before placing the curing blankets to provide the necessary moisture, allowing it to achieve maximum strength. Maintaining adequate moisture during this phase is critical for producing a durable, spall-resistant surface.

Professional Monitoring of All Operations

Cold-weather concrete placement is a delicate, technical operation that requires constant monitoring and expertise.

Temperature Monitoring

Contractors continuously monitor both the ambient air temperature and the curing concrete temperature, often using embedded thermometers. Real-time data allows staff to make immediate adjustments to supplemental heating or protection if temperatures approach freezing. Logs of temperature data are maintained throughout the initial curing period.

Quality poured concrete in a New England cold snap is the result of precision temperature control, special additive use, and diligent protection of the curing slab. Any deviation from these essential measures can lead to structural failure and significantly reduce the life span of the installed product. To discuss your cold-weather concrete needs, call Newton Total Concrete today.