Newton Concrete Resurfacing to Avoid Full Replacement

Concrete Resurfacing Newton

Eventually, all outdoor concrete (like your driveway or patio) will get worn down with small cracks and fade, also known as pitting of the surface due to exposure to Newton’s harsh freeze-thaw cycles and salt. Although you could replace the entire area, replacing a large amount of concrete is expensive, time-consuming, and very inconvenient. Concrete resurfacing is a much less expensive, convenient, and beautiful way to restore the appearance of your pavement while restoring its original performance. A resurfaced concrete surface is made using a thin layer of polymer-modified cement, which is bonded to the old surface, allowing you to have a new surface that is both fresh and long-lasting. Learning about this modern resurfacing method may save you significant time and money.

The Economic and Environmental Advantages

To achieve the greatest cost savings and minimize environmental harm through resurfacing, you have to follow the guidelines below:

- The economic benefits of resurfacing include the reduced cost of using resurfacing versus replacing your existing concrete.

- Cost savings will be achieved by not having to pay for demolition and debris removal, and excavation and hauling expenses associated with replacing your existing concrete. With resurfacing, the homeowner only pays for the resurfacing material (an overlay) and the labor involved in applying it.

- The environmental benefits of resurfacing include reducing the amount of heavy, solid waste going into local landfills and reducing the energy needed for demolition and producing all-new materials. For many people who are seeking environmentally responsible ways to improve their homes, resurfacing represents a very attractive option.

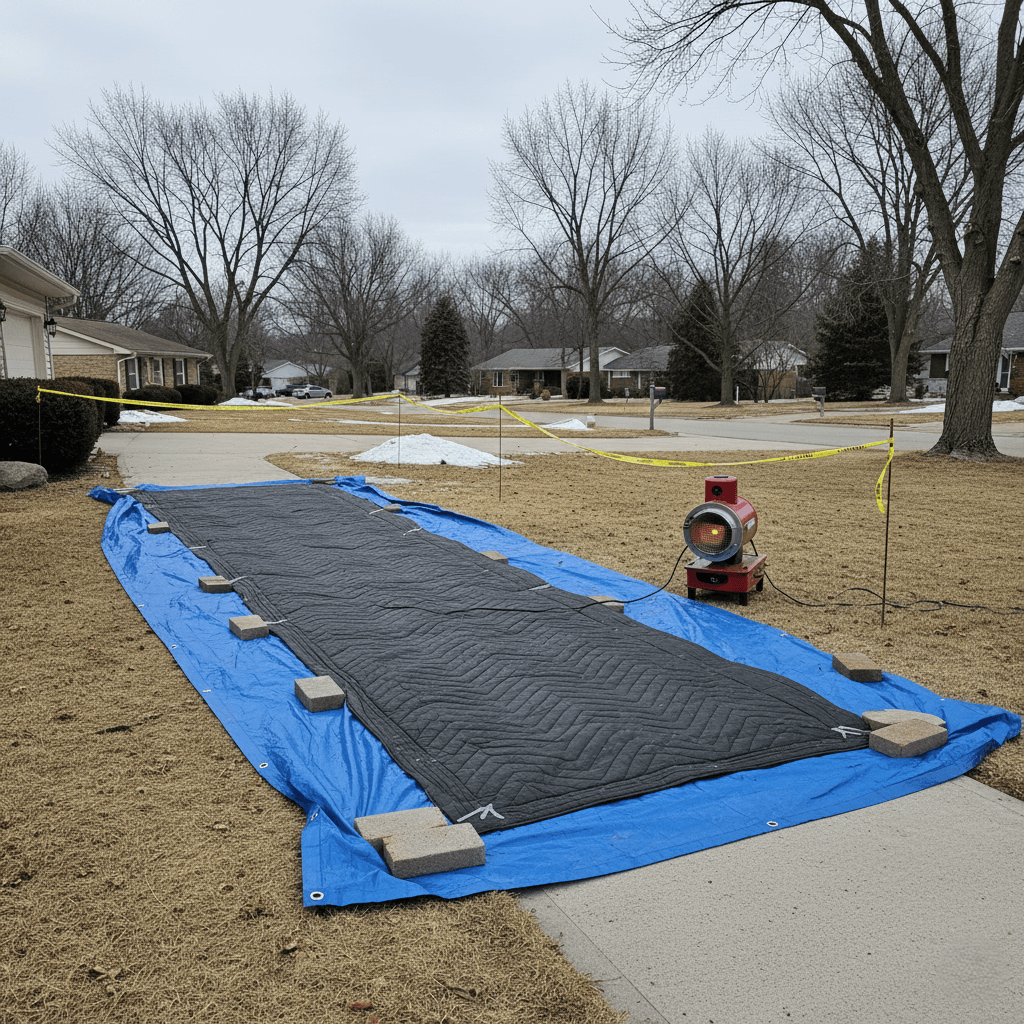

The Preparation and Structural Evaluation Process

- Only when the existing slab has been deemed structurally sound may resurfacing take place. The proper preparation of the old surface is directly related to how successful and long-lasting the new overlay will be.

- Ensuring the substrate integrity is a critical component of the preparation phase.

- Before applying the new overlay, the contractor must assess whether there is serious damage to the structure of the existing slab or whether there has been excessive settling. While resurfacing can cover minor cosmetic cracking, large structural issues (such as a basement window being located where a foundation has sunk) will require repair before resurfacing can take place. Therefore, we verify that the existing slab is sufficiently stable to support the new overlay without additional movement.

- Surface cleaning and preparation are another key component of the preparation process.

- In order to prevent the new overlay from delaminating from the old surface, maximum adhesion between the two surfaces is necessary. Before applying the new overlay, the surface must be thoroughly cleaned to remove dirt, oils, sealants, and efflorescence.

- Preparing the surface for the new overlay often requires one or more of the following processes: acid etching, mechanical scarifying, or grinding to expose a clean, porous profile. Once the surface is prepared, the polymer-modified cement will adhere both chemically and physically to the original surface.

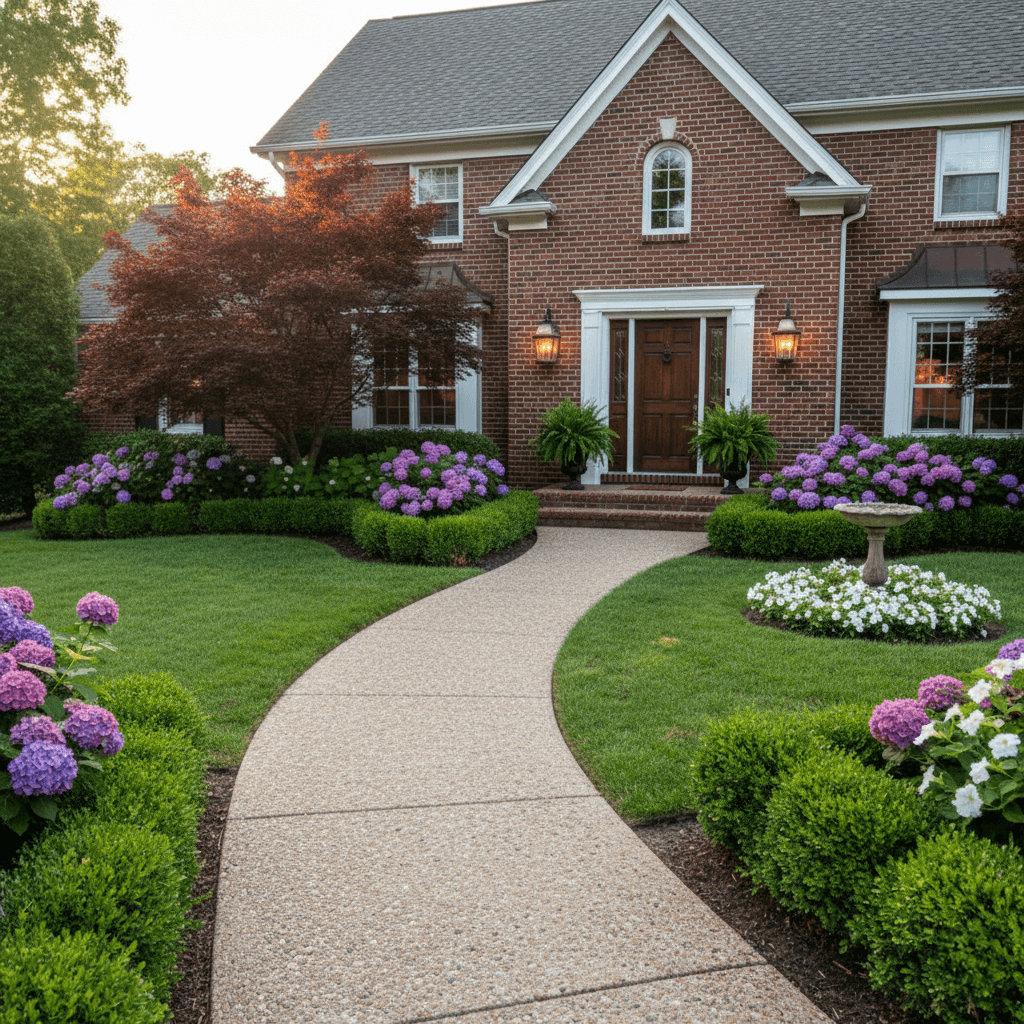

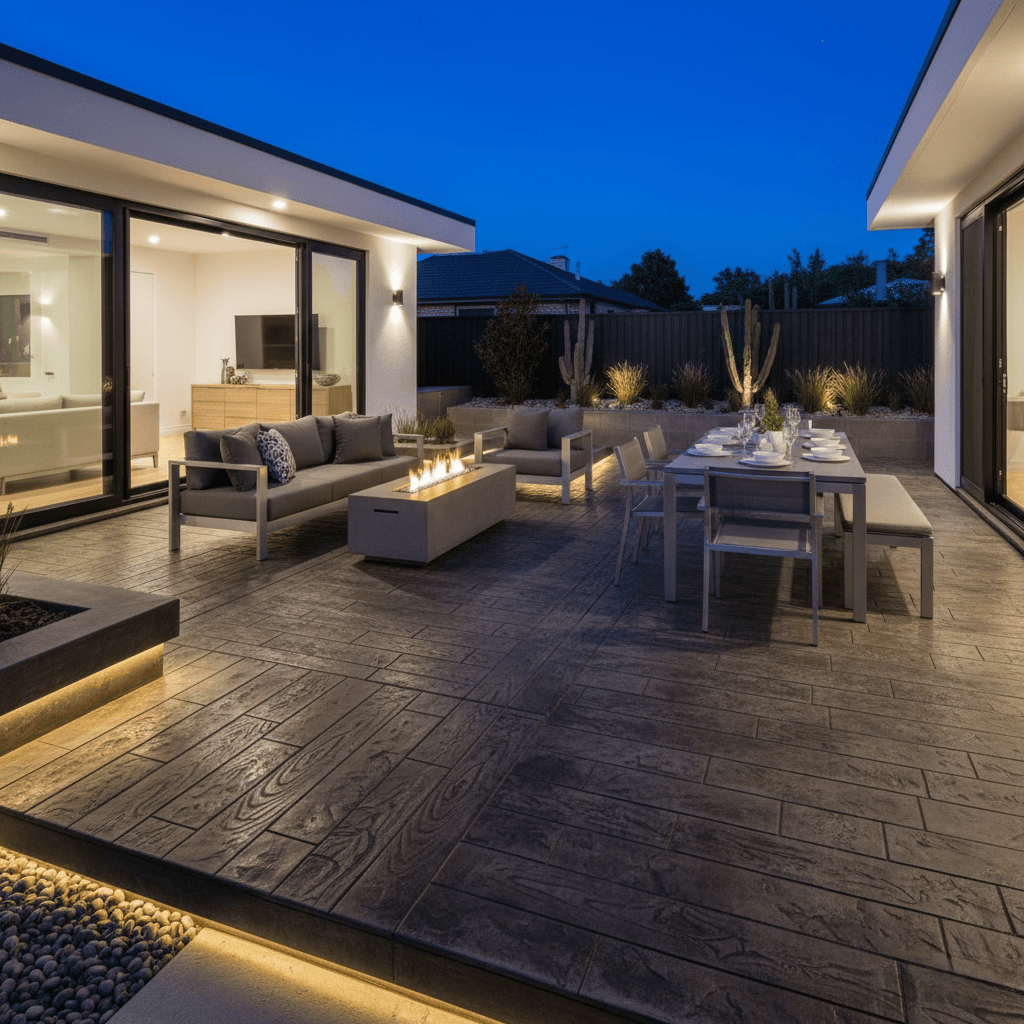

The Esthetic Versatility of Concrete Resurfacing and Customization

- Concrete resurfacing is not only a way to fix damaged surfaces but is also a method to dramatically transform the appearance of the surface to improve curb appeal.

- The color of the overlay material can be customized with a variety of colorants, including integral pigments and topical stains.

- Using the colorants available to you, you can choose colors that complement the exterior trim of your house or even the brickwork, ranging from light earth tones to rich and vibrant colors. Since the overlay material can be colored to create virtually any color you want, an old gray surface can be transformed to have either a modern or traditional color scheme.

- The overlay material can also be created to have decorative finishes similar to those found in high-end paving stones such as slate, tile, flagstone, and brick. As long as the original surface is plain, the overlay will give you the opportunity to completely transform the decorative aspect of your surface. We use special stamping tools and stencils to create complex patterns that can give your surface a high-end look at a small fraction of the cost of installing natural stone or pavers, thereby adding significantly to the value of your property when you live in a historic area such as the Eliot Memorial Bridge.

The Durability and Longevity of the Overlay Material

- Modern resurfacing materials are formulated to be stronger and more pliable than regular concrete, making them more resistant to the weather conditions typical of New England.

- The added polymers to the resurfacing material make it less prone to wear due to abrasion, chemicals, and the freeze/thaw cycle.

- If a resurfaced driveway or patio is properly installed and sealed, it should last for decades.

- Applying a high-quality sealer after the completion of the resurfacing project protects the new surface from damage caused by UV rays, water penetration, and staining.

- The protection provided by the sealer must be maintained by sealing the surface every few years. When properly done, it will protect the new surface and keep it looking great for years to come, and help extend the time until a costly resurface or repair is required.

Quality Application and Sealing

For homeowners in Newton who wish to improve the appearance and performance of worn concrete without the expense and hassle of a full replacement, resurfacing is a wonderful, durable, and practical solution. Due to the fact that this is a specialized form of application, it requires accurate preparation and skillful application to provide the best possible adhesion and a pleasing finish that will withstand the test of time. Contact Newton Total Concrete to discuss your concrete resurfacing requirements.